Rapid prototyping is the process of quickly developing actual physical pieces to use for testing the design, in shape, and functionality of any style. Standard developing operations will take several weeks or several weeks to setup, not to mention lots of money. This is why rapid prototyping is indeed crucial. It not saves time, but dollars as well, generally.

Service Companies

There are many businesses that supply rapid prototyping services, and there are numerous services available from them. A few of the well-known services are evaluated listed below.

Kinds of Developing

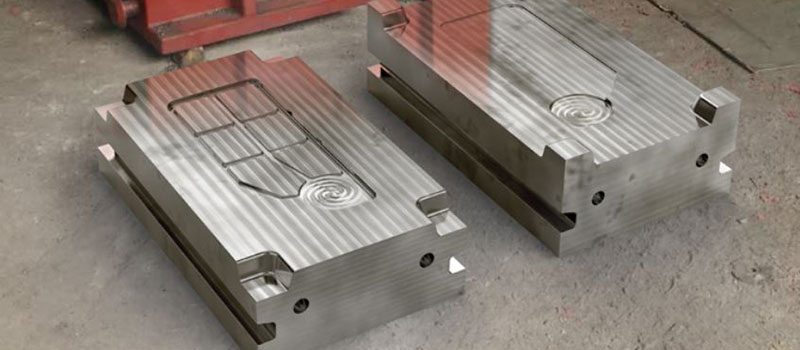

There are two standard types of prototype producing: additive and subtractive. Subtractive operations entail older tactics for example milling such as CNC milling. Machines begin with an extra-large obstruct of substance and progressively eliminate substance up until the part is finished. Additive processes, including 3D printing, are comparatively modern and they also job by producing level after level of substance before the aspect is finished. Each varieties of developing will take hours or time to finish but each and every approach has exclusive benefits.

3D Printing

1 swiftly-developing method is known as 3D printing. It is amongst the most up-to-date and a lot reasonably priced processes available. It is an ingredient approach where levels of substance, often a plastic-type or even a photopolymer, are made up one-by-one over several hours to create parts. Some printers may even use actual aluminum. There are several approaches to make the levels. One entails an inkjet type program, in which a liquid photopolymer is sprayed throughout a desk from the model of the covering and dehydrated by sun lighting fixtures. Yet another process extrudes tiny strips of plastic, like a small hot glue firearm, plus a mechanized placing method areas the plastic-type material within the proper areas to produce a coating using the proper outline. Still one more method uses a laser to aim at the layer of natural powder to fuse tiny areas with each other to create a coating with the appropriate summarize. There are more solutions available, but this is a good breakdown of this procedure.

SLA is probably the oldest and the majority of preferred rapid prototyping methods on the market. It gives you an excellent degree of durability, area fine detail, and price. SLA is definitely an ingredient procedure that requires a vat of water photopolymer. A laser light method treatments the proper sections of every coating.

Picky Laser beam Sintering SLS

Discerning Laser light Sintering, or SLS, is another preferred service giving. It will always be more expensive and components usually have a rougher finish than SLA but you can find a larger variety of resources accessible, including steel, plastic-type, porcelain and glass.