Let us be honest we are for the most part human (maybe some more than others) and one steady that we share, beside the self-evident, is that we commit errors. The individuals who work in item advancement circles are no exception…in truth it is the demonstration of disappointment that occasionally prompts our most noteworthy achievements. Shockingly, achievement tested turn of events regularly brings about an apparently ceaseless pattern of configuration test-overhaul test-rehash. This eats into the spending plan, however the task course of events also. Clearly, one sure-fire approach to get the chance to advertise quick and on spending plan is to recognize structure openings right off the bat in the plan procedure regularly actually quite difficult. Commonly mistakes can be discovered during the prototyping stage, when seat models are moderately modest and changes can be fast. Yet, blunders that are found further downstream are typically progressively costly to cure. Also that time lost somewhere down in the advancement cycle is not just hard to recuperate, yet in addition expensive. And afterward there are the mistakes that are found not being developed or testing, however (might we venture to state it…) after the item hits the hands of the client.

Plastic segments from inside components and supports to corrective walled in areas and interfaces-clearly require testing also. Life testing, rehashed activation, drop testing, security, simplicity of get together, serviceability, manufacturability, feel, ergonomics are extremely significant elements that apply to plastic parts. Previously, acquiring a short run of genuine plastic parts to work test required a ton of cash and a long lead time. On the off chance that a designer needed to test a couple of parts he was consigned to SLA (stereolithography) or RTV (cast urethane) parts.

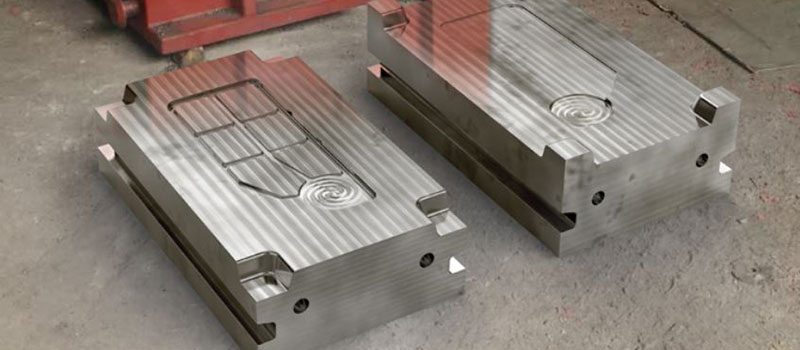

Luckily, late mechanical advances in the domain of rapid tooling have given item planners new alternatives. A couple of organizations have effectively sharpened their procedures to such a point, that they can create genuine plastic segments that occasionally contend no holds barred with SLA and RTV as far as both cost and conveyance. The players in this game range from sellers who utilize just CNC machining (which regularly requires uncommon part structure concessions) to the individuals who can deliver a close to creation quality part that can be utilized for spanning into creation as hard tooling is fabricated. Frequently a straightforward plastic part delivered from a CNC cut instrument is all that is required, however on the off chance that the necessity is a test part that will intently reflect a creation part, it bodes well to utilize the procedure that intently reflects creation tooling.